|

Marketing,

Production, and Service Rights for this system have recently been

handed over to Hans Erik Misser ApS.

Wheel

Monitoring reduces:

·

Wheel

maintenance costs

·

Vehicle

& track

down-time

·

Wheel

inspection costs

·

Track

& component

damage

·

Ground

transmitted vibration

·

Environmental noise impact

Wheel

Monitoring Pays Off

The need for

early warning and detection of irregularities on running

wheels such as flats, corrugation and out-of-round has dramatically

increased with the application of new tread materials, higher speed

and an increased public awareness of noise and vibration abatement.

Continuous

wheel monitoring not only complies with such demands but also offers

considerable savings in terms of more cost -effective wheel

maintenance procedures and reduction of wear and damage on rails and

car components

Environment Environment

The WMS as a

whole and the rail mounted sensors and assemblies in particular have

been designed to operate reliably under the often extreme

environmental track conditions such as very wide temperature range,

mechanical shocks, occasional flooding, high electromagnetic

interference, rodents, grease, dirt, etc.

An

accelerometer requires virtually no calibration or maintenance. It

has no delicate moving parts, it covers a very wide speed range and

temperature range and no temperature drift compensation circuits are

needed.

Different types of sensor

mountings are available. Mountings do not interfere with ballast and

sleepers.

All assemblies of the WMS

have passed severe electrical and mechanical vibration and shock

tests according to relevant international test standards

Easy Upgrading

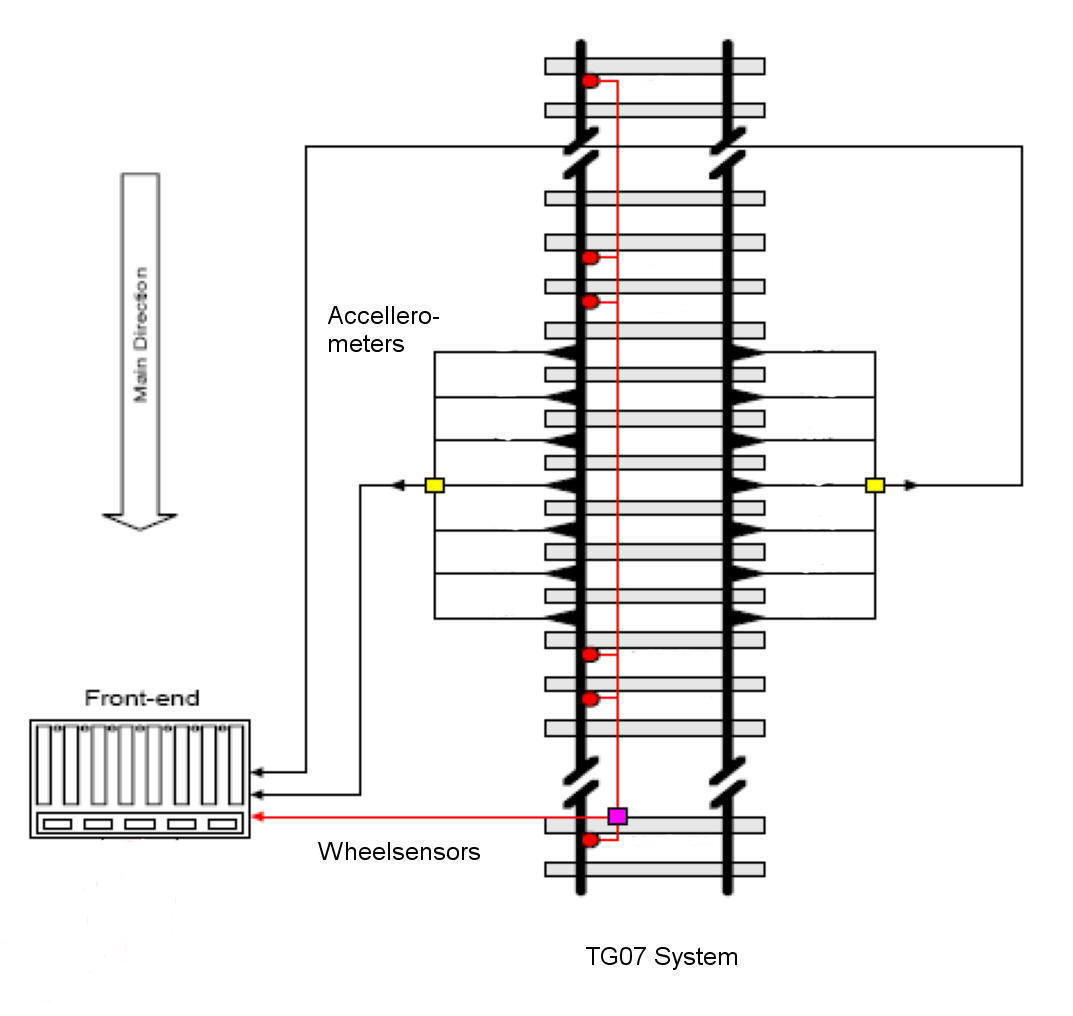

The

series of WMS offers a modular design and is readily upgraded by the

user himself e.g. from a TG.07 to a TG.14 or TG.21. The signal

processing software and system software are identical for all three

versions, only additional modular hardware is required for adding

more channels.

Unattended Operation

The WMS track-site equipment

has been designed for maximum reliability and ease of maintenance.

Data are transferred continuously and automatically to the OCC

(Operating Control Center). All user-defined functions and set -ups

are controlled from the OCC terminal. All user-defined functions

and setups are controlled from the OCC terminal. An error log is

automatically sent to the OCC and a trouble-shooting programme

allows remote diagnosis of system faults.

Main Wheel Parameters

·

Wheel

Flats

·

Out-Of-Round

·

Kurtoisis

·

Corrugation

·

Impact

signal

values

Vehicle & Wheel identification

Identification may take

place an the basis of time stamps or fully automatically by

connecting an AVl system to the WMS. The AVl (Automatic Vehicle

Identification) system is an option.

Data Transfer & Communication

The WMS connects with the

remote OCC via a leased public telephone line and a serial Modem

connection or LAN connection

Selecting the Installation Site

Location

The main track where most

cars run, provides the optimum cost/benefit ratio for the system.

The track must be straight with welded joints and the distance to

nearby switches and crossings should preferably be at least 50

metres.

System Configuration

The accuracy

increases with the number of full wheel revolutions measured during

a train passage. The TG.07 measures at least one full revolution and

the TG.21 covers 4 full revolutions during one passage. TG.21 is

required for OOR (Out-Of-Round) detection. Other factors may also

influence the proper choice of system configuration.

Passage

Speed ODS-Caltronic should be consulted in each case as the ideal

speed range depends on traffic and site conditions.

Track-side Cabinet

The IP65

stainless steel cabinet is configured according to WMS version. The

picture shows a fully configured 42 channel TG.21 system.

FFT

Analysis

The WMS uses

an advanced FFT algorithm to analyse and calculate various wheel

parameters.

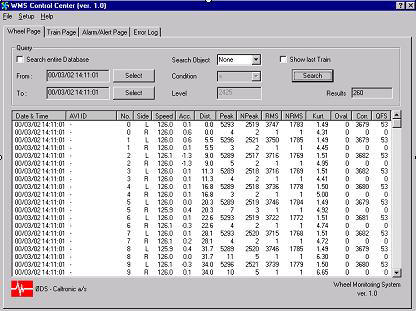

User-Software with

Database

A standard

PC is recommended at the OCC as a dedicated WMS communication

terminal on which the ODS-Caltronic user software is installed. All

WMS functions are accessed and monitored from the user software and

fault diagnosis software |